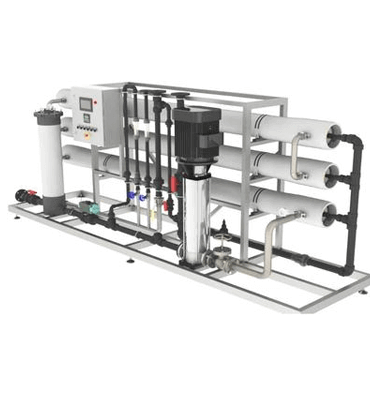

Brackish Water Industrial R.O Systems

Designed to produce low dissolved solids water from tap or well water, these RO systems use high efficiency reverse osmosis membranes. The product water is used in applications such as water stores, whole house, ice makers, humidification, misting and a wide variety of other applications. Part of the L-series family (other systems include L and XL series), these systems treat higher TDS water and thin film membranes and FRP membrane housings. All high pressure lines and components are made of corrosion resistant materials. The operating pressure is between 200 and 250 psi. Careful design steps are taken to minimize the highly corrosive nature of these brackish waters. These reverse osmosis systems use the proven, reliable components and are mounted on a sturdy powder-coated metal frame. There are numerous design details learned from years of experience that are incorporated in our water filtration systems. Our process and fluid design ensures an optimum membrane life and minimizes the membrane fouling.

Standard Features

- Status indicators

- Motor starter

- NEMA 12 enclosure

- Low pressure switch

- High pressure switch

- Liquid filled pressure gauges

- Permeate conductivity monitor

- Permeate & concentrate flow meters

- Powder coated carbon steel frame

- 8” TFC spiral wound membranes

- Stainless steel multi-stage pump with TEFC motor

- FRP membrane housing

- 5 micron cartridge prefilter

- 460V/3Ph/60Hz power supply

- PLC based control panel

- Programmable time delay and set points

Operation Specifications

- Feed water pressure: 20 to 80 psi

- Operating pressure: 150 to 250 psi

- Hydrogen Sulfide must be removed

- Turbidity should be removed

- Max. iron content: 0.05 ppm

- Feed water TDS: 0 to (1,000 or 3,000 or 5,000 ppm)

- Equipment upgrade for TDS over 5,000 ppm

- Hardness over 1 GPG requires antiscalant dosing

- pH tolerance range: 3-11 Max.

- Silica Tolerance: 60 ppm @ 60% recovery

- Operate at higher TDS by lowering recovery

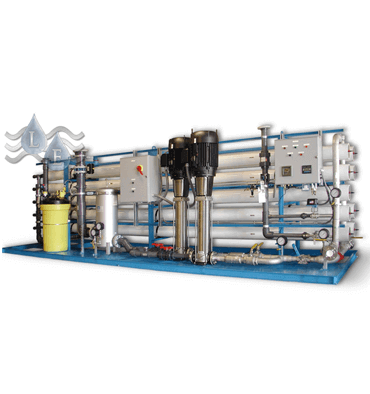

Sea Water Industrial R.O Systems

From water-makers to industrial sized Seawater Purification, we offer a full range of systems. Our units are manufactured to eliminate a large amount of salts and other minerals from seawater using RO. Our equipment does the filtration by employing a high-pressure pump to salty water forcing it through semi-porous membranes denying salts and other organics from flowing through.

The membranes are only tasked to remove dissolved solids while dividing the feed water into purified water and rejected concentrated salts. The salts and other organics are thrown into the brine stream then flushed into a drain. At the end we have purified water that has 99% less dissolved salts. These sea water RO systems have the power to purify extremely high TDS water.

Seawater RO systems are usable anywhere from yachts to municipalities. It’s important to choose the correct materials of construction to handle seawater (which is highly corrosive). Pure Aqua, Inc. uses materials such as Duplex SS 2205, SS 2207 or Monel, and SS 904 to guarantee a longer operating life and less maintenance.

Seawater Reverse Osmosis (SWRO) is a reverse osmosis desalination membrane process that has been commercially used since the early 1970s. The typical single pass SWRO system consists of the following components:

- Intake: well or open water

- Pre-treatment: Filtration and chemical dosing

- High-pressure pump: to achieve the needed pressure

- Membrane assembly: to perform the desalination process

- pH adjustment: to adjust the alkalinity or acid level

- Disinfection: to prevent any bacterial or organic growth

Standard Features

- Stainless steel frame

- Heavy duty 5 micron cartridge prefilter

- Sea water resistant SS pump

- Microprocessor/PLC based control panel & VFD

- Glycerin-filled 316 SS pressure gauges

- Product & reject flow meters

- TFC spiral wound membranes

- FRP membrane housings

- 460V/3ph/60Hz power requirement

- Low & high pressure switches

- Permeate TDS monitor

- Stainless steel high pressure piping

- Stainless steel throttling valve for reject stream

- Automatic feed shut off valve

- Energy recovery on 64K GPD and larger

Operation Specifications

- Max. feed water temperature: 42°C

- Feed water pressure: 40 to 80 psi

- Operating pressure: 700 to 1,000 psi

- H2 S, turbidity and organics must be removed

- Max. iron content: 0.05 ppm

- Feed water TDS: 10,000-42,000 ppm

- Equipment upgrade for TDS up to 50,000 ppm

- Antiscalant dosing is required pH tolerance range: 3-11

- Biological or organic content must be removed

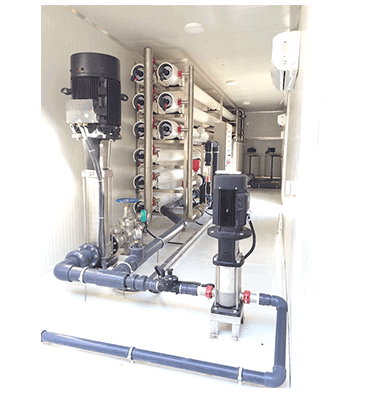

Containerized R.O

ECOPURE supplies any type of water treatment in a containerized version. From desalination plants to emergency resonce units.ECO PURE designs ready-to-use containerized desalination plants that can produce up to 1000 m3/day of drinking water from different sources and with varying salinities.

The desalination core process is reverse osmosis where semi-permeable membranes are used.

Why containerization?

Containerized plants have many advantages over built-in plant room installations:

- Plug and play unit

- Quick installation

- Limited civil work (only container foundation)

- Small foot print

- Easy transportation

- Mobile: useful for construction sites

- Turnkey delivery: piping, cables, air conditioning

Containerization of a water treatment plant does not only include the supply of a container, it includes the complete installation of the plant:

- Connected piping between equipment pumps, vessels, skids, tanks

- Cabling and wiring of pumps and instrumentation inside the container to main control cabinet.

Container equipment

We can deliver our systems in insulated (20 or 40 ft) containers. Containerization includes all piping and fittings connected, all cables and wires connected to instrument and control cabinet. This is a “plug and play” unit supply.

The container will be mounted with one side door, one inlet/oulet (terminal point), one roof hatch, one side door and floor drainage. A sun roof can be offered on request to limit the inside temperature in the container if extreme conditions have to be considered.

The container can be air cooled on request. The Airco is a split-unit and the outdoor part will be placed next to the container.

The design of the water treatment plants is always custom made and is subject to modifications depending on the water quality.

Reverse Osmosis units often required pre-treatment for the following parameters:

- Suspended solids

- TOC, COD/BOD, hydrocarbons

- Iron and manganese

- Hardness

ECO PURE provides all kinds of pre-treatment required before your RO, according to your water analysis and process requirements.

Plant Size / Standard container

Depending on the plant size, containerised plant in 20 or 40 ft container(s) are available

Our Works

Featured Products

WE ALSO PROVIDE PARTS ACCESSORIES, AMC CONTRACT AND FILTERS SERVICES AT YOUR HOME / INDUSTRIES / OFFICES ETC